Machine knives and Industrial knife Grinding

Tool grinding is the process by which cutting tools, such as milling cutters, drills, saw blades, lathe tools, or machine knives, are ground to sharpen their cutting edges. This process is crucial for ensuring the efficiency and precision of the tools and extending their service life.

What steps does tool grinding involve?

- Detect wear

- Cut off if necessary depending on the degree of bluntness

- Set up the grinding machine for the appropriate cutting tool

- Install the appropriate grinding wheel

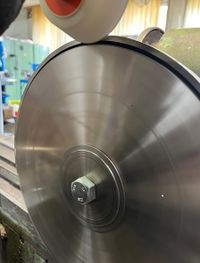

- Sharpen the carbide tool or circular blade

- If necessary, have it coated